-

ِSaudi Arabia , Oman

-

Call Us On

+966 11 4777187

-

Mail Us @

RE AR burner or heating elements

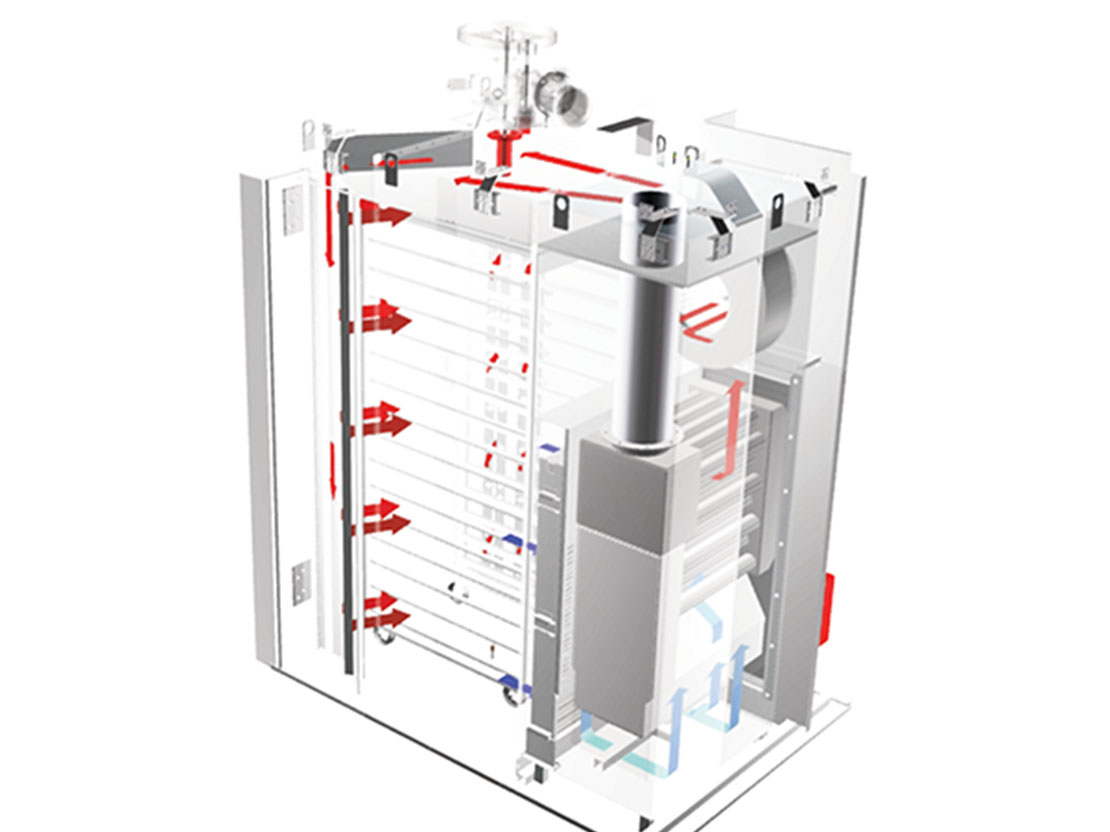

The success of this rotary oven is in the quality of the initial design where the design input was to produce ovens made to last over time. Proof of this are the large thicknesses and the quality of the materials used, the large baking chamber, the special route taken by the fumes and the robustness and efficiency of the heat exchanger. This model has rear access to the exchanger. Available inelectric, burner gas or gas-oil, biomass-pellet versions.

Control panel: Electromechanical, Digital or Touch screen

The VORTEX rack oven line has been designed and built by Logiudice Forni. The company guarantees and certifies that the product is 100% MADE IN ITALY. Rotary ovens are set apart by their extraordinary baking evenness and quality.

Rotary ovens with one or two baking trolley capacity for 18 various size trays, depending on the model.

Gas, diesel, pellet burner operating system or with electric resistances located at the back right (right side upon request).

The oven is made entirely of stainless steel, with the exception of the steam generator.

Standard supply bayonet (hanging) trolley connection. Turntable platform or mechanical trolley lift available upon request.

Powerful steam generator in an accessible position with sections that can be individually removed and replaced, in direct contact with the combustion chamber so as to ensure an ample and prolonged production of steam.

Heat exchanger in 4 mm AISI 309-S refractory steel, resistant to high temperatures.The circular section tubes with notable surface area guarantee excellent performance with low energy consumption.

The passage of air in the upper part of the oven ensures greater air flow with low circulation speed.